KWL.Precision machining of high-end parts

KUWAI-LIAN focuses on CNC milling machine processing and turning and milling processing, and cooperates with customer orders to achieve the most effective integration, from drawing evaluation → order processing → surface treatment → shipping inspection, etc., to provide complete, accurate and efficient customized services.

KUWAI-LIAN also has rich experience in providing customized automated special machines to global customers. We use advanced technology and high-quality materials to produce products, ensuring that each product has excellent durability and high tensile strength.

Our products and equipment are highly appreciated by customers around the world for their precise construction and dimensions, ease of use and maintenance. These advantages not only improve usage efficiency, but also provide customers with an excellent usage experience. We look forward to working with you to create more opportunities for success.

Customized Machines Development

We specialize in developing customized machines to meet the diverse manufacturing needs of our customers. From design to production, we are committed to delivering efficient and high-quality solutions.

High quality inspection system

We offer a variety of semiconductor-related parts manufacturing to support our customers' needs in advanced manufacturing technologies.

Green energy electric vehicle

As a certified manufacturer for green energy electric vehicles, we are dedicated to producing high-quality components that meet environmental standards. Our technologies and processes strictly adhere to eco-friendly principles, promoting the development of the green energy industry.

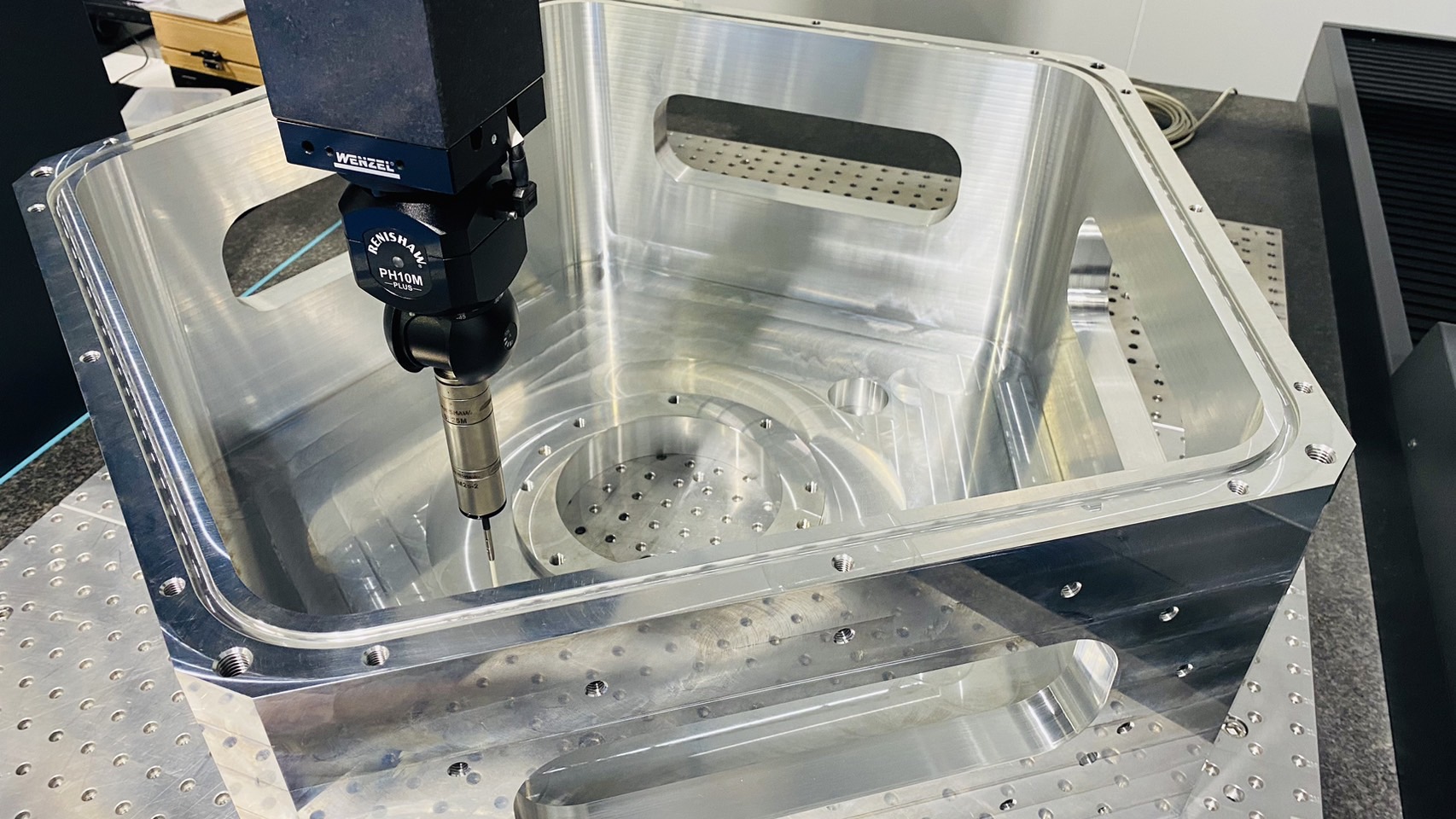

Large cavity processing for semiconductors

We utilize advanced inspection equipment to ensure precision and consistency throughout the production process.

The best choice for precision parts processing

High efficiency . High-precision professional processing

Whether it is fine or large-scale machined parts, metal or industrial plastics, etc., from development samples to mass-produced products, key parts required in various fields can be processed according to customer drawing requirements.

Accurately handle the key steps in semiconductor manufacturing

Professional supply of customized equipment

KUWAI-LIAN provides a variety of semiconductor equipment, including wafer tearing machines, automatic wafer readers, wafer inspection machines, etc. These devices handle critical steps in the semiconductor manufacturing process with precision and efficiency, ensuring the accuracy and efficiency of the production process. KUWAI-LIAN is committed to providing advanced technical solutions to meet customers' high requirements for quality and production efficiency.

News

Visit and Exchange with Kajiki Industries Co., Ltd.

First Meeting: KWL and Kagoshima Companies Exchange

KWL Semiconductor Inspection Equipment Successfully Shipped, Serving the Global Market

Overcoming Pandemic Challenges, KWL Efficiently Completes Equipment Production

KWL Achieves AS9100D 2016 and ISO 9001 2015 Quality Certifications

Demonstrating Excellence in Quality Management through Dual Certifications

Five-axis precision machining example

KUWAI-LIAN has professional processing technology to achieve various processing characteristics and precision requirements. The five-axis processing machine from DMG MORI was selected as the processing equipment. The main feature is that the X and Y axes are driven by linear motors and equipped with an NC cradle-type rotating platform, providing customers with stable, efficient, and sophisticated products.

The processing example is an aluminum alloy material processing product, using a five-axis machining machine to process curved surface features. The production process will achieve the goal of process optimization through program modification and tool selection.

Semiconductor equipment examples

From the early days to now, KUWAI-LIAN has supported the design and manufacturing of customized equipment in various fields, matching different equipment according to customer needs, and conducting in-house R&D and design.

The video showcases an automatic semiconductor wafer inspection machine (Auto ID Reader)KC-1E01-A3-101. It is designed for 12-inch wafers and operates in a Class 1 cleanroom. The machine can automatically open and close the FOSB, detect wafer presence, and recognize wafer IDs (capable of identifying more than seven types of characters).

Choose KWL, Choose Excellence

Based on its professional semiconductor equipment supply, KUWAI-LIAN has rich industry experience and technical solutions. We are committed to meeting customer needs efficiently and accurately and earning their trust with quality and service standards.